High performance MBS Impact Modifier L-200 Resin impact modifier for pvc products

L-200 is a type of transparent MBS impact modifier. It has dual benefits with balance of mechanical properties and optical properties. It is environmentally friendly and mainly used to produce clear PVC sheet and film with balance of transparency and impact strength.

High performance MBS Impact Modifier L-200 Resin impact modifier for pvc products Specifications :

| Price | Contact us |

| Place of Origin | China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Delivery Detail | 3days--7days |

High performance MBS Impact Modifier L-200 Resin impact modifier for pvc products Detail Introduction :

Transparent MBS Impact Modifier L-200

Description

L-200 is a type of transparent MBS impact modifier. It has dual benefits with balance of mechanical properties and optical properties. It is environmentally friendly and mainly used to produce clear PVC sheet and film with balance of transparency and impact strength.

Key property

Promote fusion

Balance of transparency and impact strength

Good heat stability

Improve melt flow ability

Product index

Specification | L-200 |

Appearance | White, free flowing powder |

Bulk Density | >0.36 g/cc |

Particle Size (16 mesh) | ≤1.5 |

Volatile content | ≤1.00 |

Specific gravity | ≤1.10 |

Basic formulation for following tests

Ingredients | 0# Control | 1# Competitor | 2# L-200 |

PVC(K-57) | 100.00 | 100.00 | 100.00 |

Tin stabilizer | 1.20 | 1.20 | 1.20 |

Transparent processing aid P-20 | 1.00 | 1.00 | 1.00 |

Int. lubricant LU-60 | 1.00 | 1.00 | 1.00 |

Ext. lubricant LU--74 | 0.50 | 0.50 | 0.50 |

MBS Competitor | -- | 5.00 | -- |

L-200 | -- | -- | 5.00 |

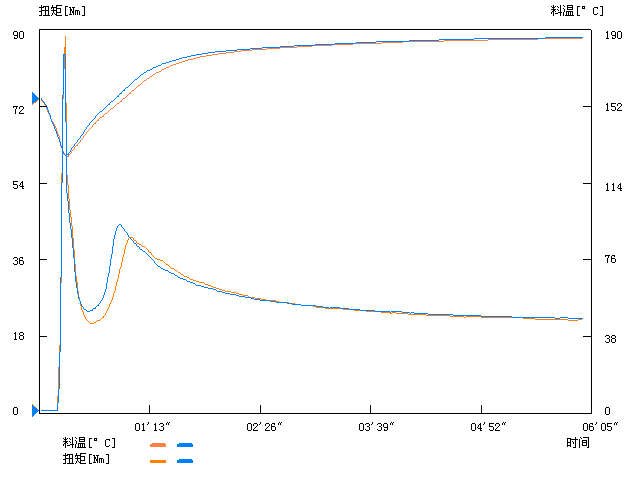

Fusion properties comparison

Test conditions | 160℃ 60rpm | ||||

| |||||

Fusion data Type | Fusion time (S) | Highest torque (Nm) | Lowest torque (Nm) | Equilibrium torque(Nm) | |

1# Competitor | 41 | 43.3 | 20.3 | 22.3 | |

2#L-200 | 37 | 46.0 | 23.5 | 22.4 | |

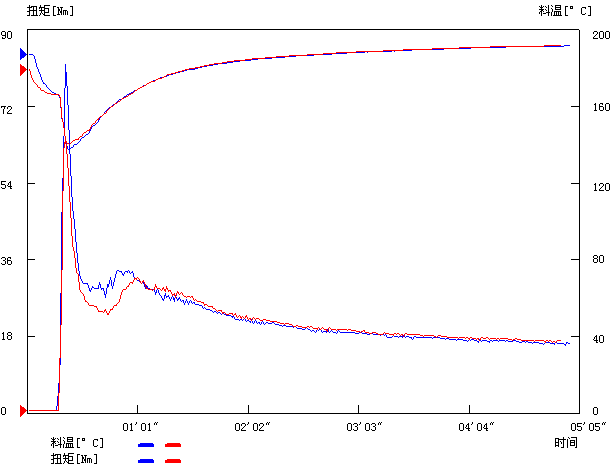

Test conditions | 190 30rpm | ||||

| |||||

Fusion data Type | Fusion time (S) | Highest torque (Nm) | Lowest torque (Nm) | Equilibrium torque(Nm) | |

1# Competitor | 41 | 30.9 | 23.7 | 16.6 | |

2# L-200 | 37 | 33.0 | 27.3 | 16.4 | |

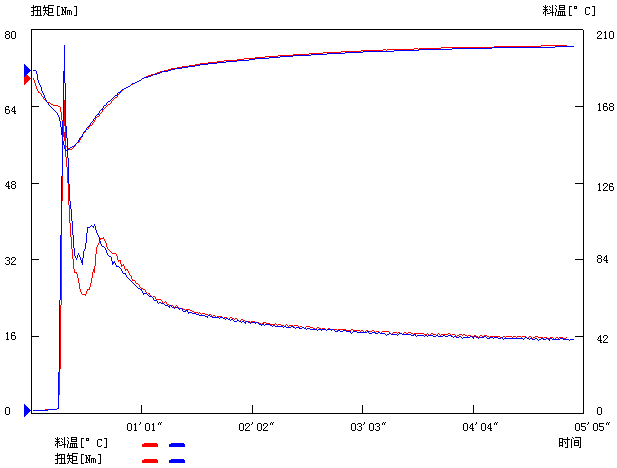

Test conditions | 190℃ 60rpm | ||||

| |||||

Fusion data Type | Fusion time (S) | Highest torque (Nm) | Lowest torque (Nm) | Equilibrium torque(Nm) | |

1# Competitor | 21 | 36.5 | 24.8 | 15.6 | |

2# L-200 | 16 | 39.2 | 31.0 | 15.6 | |

Optical properties comparison

Type | Haze |

1# Competitor | 4.02±0.04 |

2#L-200 | 3.85±0.03 |

Dynamic thermal stability

Test condition: double-roller mill temperature190℃ Thickness: 0.5mm

YI at different time Test standard: ASTM E313-00

Type | 3' | 5' | 7' | 9' | 11' | 13' | 15' |

1# Competitor | 0.95 | 3.20 | 4.57 | 5.68 | 6.67 | 7.85 | 8.90 |

2# L-200 | 0.99 | 3.58 | 4.24 | 5.98 | 7.08 | 8.01 | 9.17 |

Mechanical property

Pat impact: 5℃stable 20min, 25.020HZ pat 15s

Type | Thickness(mm) | Number of all samples | Number of damaged samples |

0# Control | 0.5±0.02 | 10 | 10 |

1# Competitor | 0.5±0.02 | 10 | 2 |

2# L-200 | 0.5±0.02 | 10 | 2 |

-5℃stable 20min, 25.020HZ pat 15s

Type | Thickness(mm) | Number of all samples | Number of damaged samples |

0# Control | 0.5±0.02 | 10 | 10 |

1# Competitor | 0.5±0.02 | 10 | 4 |

2# L-200 | 0.5±0.02 | 10 | 3 |

Tensile strength comparison

Test standard: GBT 1040-2006 Test condition: 23℃ 10mm/min

Type | Tensile strength (MPa) | Elongation at break (%) |

0# Control | 46.71±0.24 | 115.64±4.12 |

1# Competitor | 45.20±0.43 | 157.04±3.54 |

2# L-200 | 45.24±0.46 | 164.89±4.51 |

Metal release property comparison

Test condition: Double-roller mill temperature 196℃

Type | Sticking time(S) |

0# Control | 340±10 |

1# Competitor | 504±12 |

2# L-200 | 513±12 |